Flow Grippers for Highly Structured Surfaces SCG-HSS

- Suction rate: 270 l/min to 650 l/min

- Suction area: pin curtain with Ø 47 mm

- Lift capacity up to 250 g (horizontal and vertical)

- ESD compliant

Visitors can experience the latest solutions for various industries such as logistics, food, packaging and automotive through robot applications. Please come and see the latest in vacuum conveying technology at the show.

New

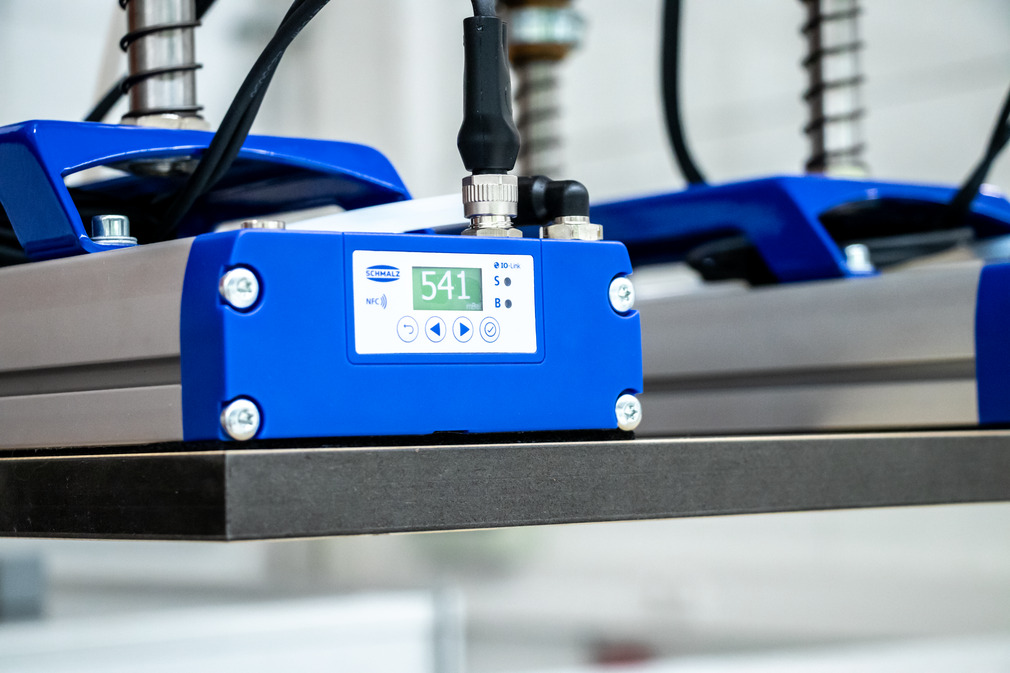

The long-established FXP/FMP vacuum grippers have undergone a model change! The lineup now includes a high-performance type equipped with an air-saving function that reduces air consumption by up to 80%, contributing to lower running costs.

Compared to the previous models, the new models are easier to maintain. The FXP/FMP can be used in various processes such as palletizing, depalletizing, and inter-process conveying of corrugated cardboard.

New

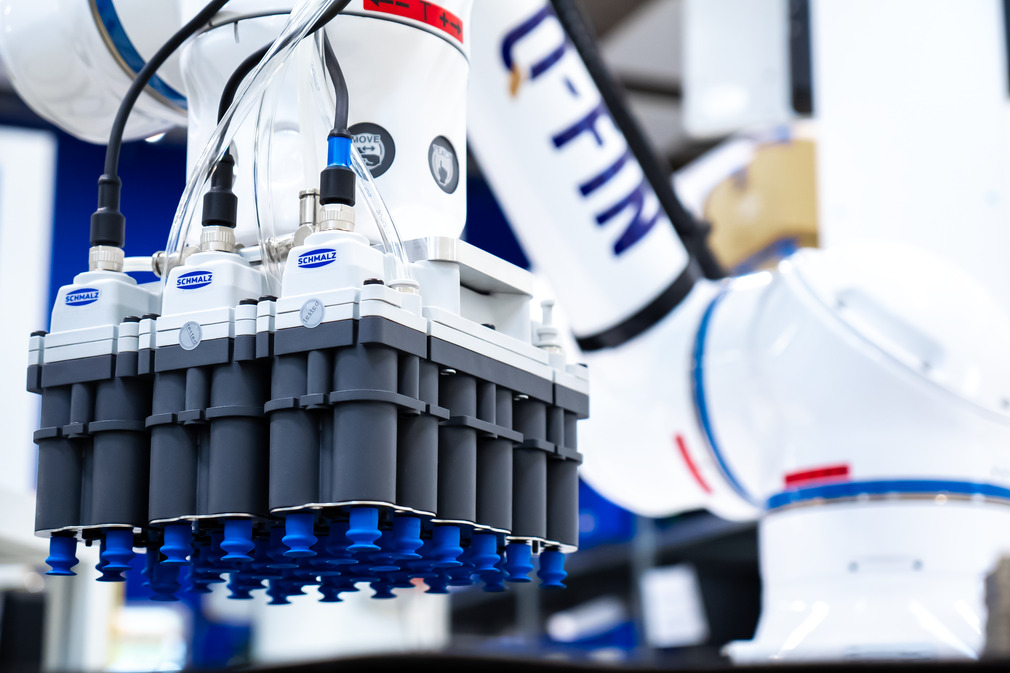

This new type of area gripper can handle workpieces of various shapes.

Since only the vacuum pad with the cylinder rod extended is effective for suction, suction can be controlled individually according to the shape of the workpiece.

Air consumption can also be reduced, contributing to lower running costs.

This assist device supports manual transfer of heavy loads. The device can be operated intuitively with one hand, so anyone can use it easily after a short training period.

It can be used in processes such as transferring and loading cardboard boxes, bags, drums, etc.

Exhibitor Seminar: Energy Efficiency x The Cutting Edge of General-Purpose Handling! Logistics Processes Grasped by Vacuum Grippers

Thursday, 4 December, 14:30–15:10

We will be holding an exhibitor seminar.

Addressing the worsening labour shortage and soaring energy costs. Discover Schmalz's latest solutions to the challenges faced by many production sites.

We look forward to your attendance.

Finger type gripper that provides flexible adjustment and delicate gripping like human fingers. Its lightweight design makes it suitable for pick-and-place operations at high speeds.

The modular structure allows the size and number of fingers to be adjusted and reconfigured to suit the workpiece.

In addition, the latest vacuum handling systems will be exhibited.