Gentle hold and full flexibility

Thanks to the FlexMat elastomer mat, openings can also be made as the tools can mill into the mat.

Plastics are lightweight and corrosion-resistant, have a high level of strength and provide electrical insulation. They enable complex shapes and therefore offer numerous advantages in the construction of electronic components. However, processing them requires a great deal of sensitivity in order not to destroy the material. This is precisely where SiSS GmbH reached its limits, as the plastic sheets used were regularly damaged during hydraulic clamping in the CNC machining center.

The installation was uncomplicated and quick.∼ Sebastian Burster, Team Leader Programming at SiSS

SiSS produces complex components and systems for various industries in Baden-Baden Steinbach. In addition to components for medical technology, the 65 employees manufacture solutions for charging infrastructure, refrigeration and railroad technology on an area of around 18,000 square meters. The wide range of production methods includes machining, welding and laser technology, sheet metal forming, powder coating and surface treatment. The company can look back on an eventful time: SiSS emerged from Medifa GmbH in November 2023, which had to file for insolvency in the fall of 2022. Weinmann Aach AG took over the production site last year and continues to run it under the name SiSS (Solutions in Style, Steinbach). Weinmann Aach is a metal solutions provider with 50,000 square meters of storage space and a wide range of sections, pipes, rods, beams, sheet metal and sheets.

From hydraulics to vacuum

SiSS manufactures plastic parts made of PVC, PTFE and acrylic glass on a CNC machining center. The company used a hydraulic vice to hold the parts in place on the worktop. "This repeatedly resulted in damage to the plastic components, which were literally compressed by the vice," recalls Sebastian Burster. He is the programming team leader at SiSS and was annoyed by the faulty processes and the size of the rejects.

Employees of the new owner Weinmann Aach drew his attention to the vacuum solutions from Schmalz. These allow different components of many sizes to be clamped quickly, easily and, above all, without causing damage. Burster immediately arranged a consultation. His goal: to gain experience with the new clamping system for the first time. Together with SiSS, the vacuum experts from Schmalz designed the fixture to suit the requirements. The solution consists of a Matrix-Plate for the machine table, which serves as a support for the so-called Innospann Steel-Plate. This in turn fixes the workpieces safely with vacuum thanks to elastomer mats. A dry-running pump with constant suction capacity provides the necessary vacuum.

Well-rehearsed technology

The MPL 600×400×28 Matrix-Plate for metalworking is made of aluminum and has milled slots on the surface. Suction-tight workpieces can be clamped directly onto it using vacuum. The special feature: The holding force, which acts over the entire surface, fixes the component with little tension and is particularly suitable for soft and thin products. The milled grid distributes the vacuum evenly over the surface. When processing the components, a sealing gasket limits the evacuated space. SiSS mounted the Matrix-Plate in a slightly elevated position on the machine table. The vacuum supply is safe and protected underneath the sheet. The specialists used the supplied connection set to connect the sheet to the vacuum generator and mount the gauge. "The installation was uncomplicated and quick," explains Burster.

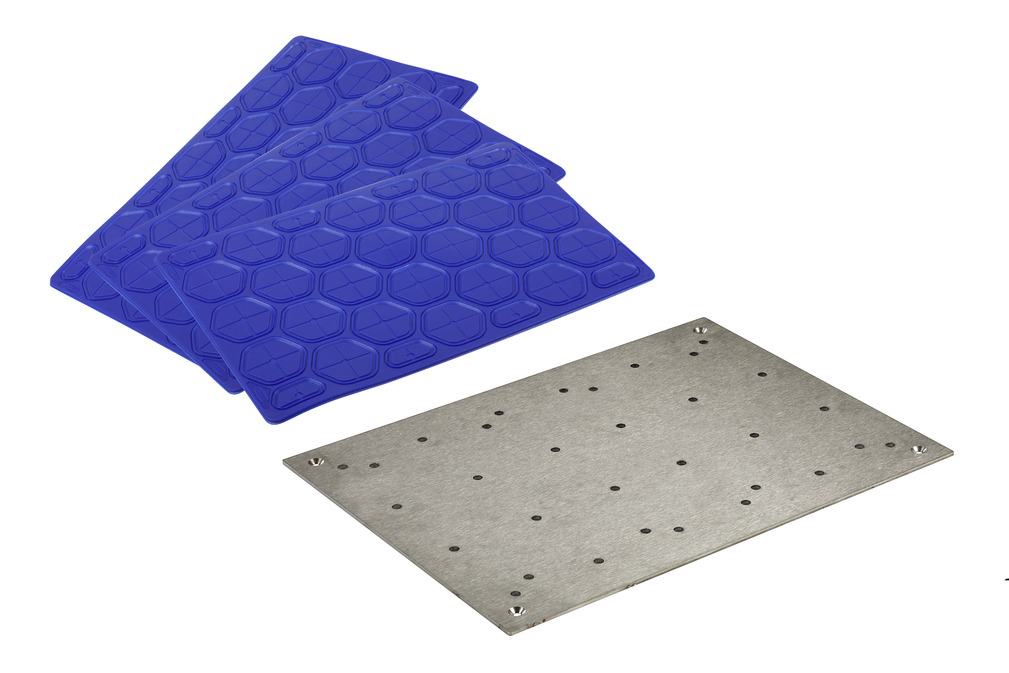

At SiSS, the Matrix-Plate carries the Innospann Steel-Plate (ISST) clamping system. This three millimeter thick sheet is made of magnetic, corrosion-resistant steel. It has vacuum holes with a diameter of seven millimetres at regular intervals. "This allows the attached clamping equipment to be supplied with vacuum, as ISST is not suitable for clamping workpieces directly. For this, applications require either the Innospann vacuum blocks or a FlexMat, as currently used by SiSS," explains Alexander Klink. He works in product management at Schmalz.

The FlexMat SFM elastomer mat fixes the plastic sheets directly. It allows openings to be made and the edges of the workpiece can also be machined, as the tools can mill into the mat. The FlexMat has nubs on the underside that grip into the holes in the Innospann Steel-Plate and guarantee a safe fit. The grid, which is also located on the underside, guides the vacuum upwards into the 32 separate suction cells. The mat is designed as a wear item to enable a wide range of processing operations. If it remains undamaged, it can be reused several times.

The robust and low-maintenance EVE-TR-40-AC3-F vacuum pump in dry-running version provides the necessary vacuum. Its sliding-vane compressor principle ensures vibration-free operation and low-pulsation, continuous pumping. Thanks to its low power consumption, it is ideal for economical continuous operation. The compact pump has an integrated fan and permanently lubricated bearings.

Successful in use

With SiSS, a specialist loads the machine manually with the raw plastics sheet. He can then conveniently open the vacuum directly at the machine table using a manual slide valve. The gauge allows employees to keep an eye on the vacuum at all times. "Our workpieces now sit firmly on the workbench without being damaged," says Burster happily. The tool mills various components from the sheet. However, the machine does not remove the parts completely, but leaves a layer height of 0.2 millimeters. Once the milling process is complete, a person removes the finished sheet, releases the workpieces manually and deburrs them. "Our employees are very satisfied with how easy it is to fix the different components," reports the team leader. And the solution is also impressive from an economic point of view: "Since we have been clamping with vacuum, we no longer have any damaged sheets. This not only saves costs," he emphasizes. "We now also work reliably and much faster than before. The accuracy and quality of the machined parts have also improved."

SiSS believes it is well positioned for the future with the vacuum solution. "The system can be easily expanded on a modular basis," explains Sebastian Burster. "If we need lateral processing with a tilted workpiece, we can use the ISBL-HD vacuum blocks on the ISST. This means we are prepared for all eventualities." Because at SiSS, the motto is: high mix - low/medium volume. This means that the company produces many different geometries, from batch size 1 to batches of 120 products, and thus offers customized manufacture. These processes can only be carried out profitably thanks to the right technology. "The support from Schmalz was great," says a delighted Sebastian Burster. "The sales staff are very friendly and helpful. They answered all our questions quickly and competently and actively supported us during the installation. This is one of the reasons why Schmalz is our first choice for follow-up projects."

The design consisting of Matrix-Plate, Innospann Steel-Plate and FlexMat ensures a gentle and safe hold for sensitive workpieces.

The Matrix-Plate is mounted in a slightly raised position on the T-slot table.

The plastic sheet is clamped without damage using vacuum.

Once the milling process is complete, the vacuum can be released and the sheet removed.

Alexander Klink (right), Product Manager at Schmalz, quickly convinced the Programming Team Leader, Sebastian Burster, of the advantages of FlexMat.

Media contact

The Schmalz press team will be happy to answer any questions you may have.